*By clicking Download for free, I agree to the processing of my data for marketing purposes and to receive promotional materials via e-mail. Read our Principles of personal data protection.

Why use customised tape design?

One of the most valued benefits adhesive tapes can bring to your designing & manufacturing process is their endless flexibility. Whether you’re looking for a better way to manufacture existing products, have a unique design or you’re just testing a prototype, customised tapes might just be the solution for you.

Why customise?

Adhesive tape can be customised into special and unique designs to fit into your product and manufacturing processes. This results in increased flexibility in product design, enhanced functionality, reduced cost and simplified handling and application.

Advantages include:

- easy-to-handle bespoke component

- various shapes and constructions (multilayer laminates)

- flexibility and creativity in your product design

- increased productivity (time saving)

- automation

- reduced costs (reduced waste)

Ways to customise

Adhesive tapes can be customised by tape manufacturers or external tape converters. With relevant tape, it is possible to:

- Slit to a variety of widths and lengths to fit the production process

- Die-cut into many shapes (standard or according to customer specification)

- Laminate with further materials for additional functionality

- Adapt die-cut shapes in a convenient format for ease of application

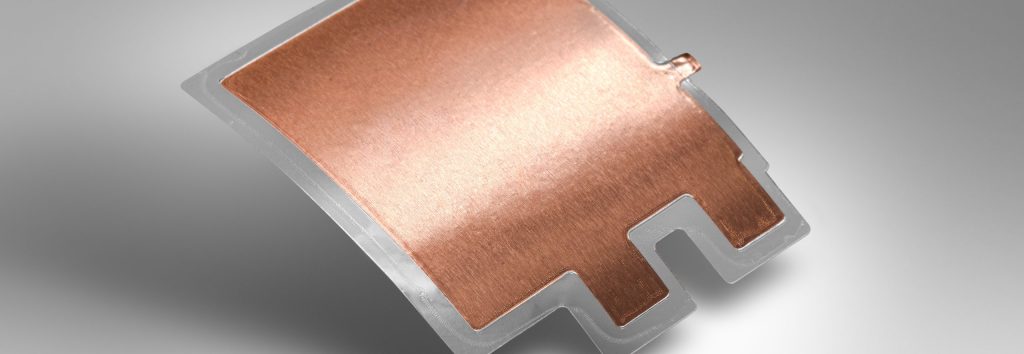

Bespoke die-cut solutions

High-quality tapes offer versatility and workability to designers and manufacturers in many industries. They can be specifically designed for any product or application and die-cut into countless shapes. Whether you’re looking for complex shapes or simple dots, PPI Adhesive Products Ltd have the capacity to produce your design. All die cuts are produced from the vast adhesive tape ranges PPI manufacture on site. Technical Adhesive Products Ltd (T.A.P.), operating within PPI group has the combined converting capabilities to manufacture products completely in-house.

Our capabilities include:

Rewind Slitting: With more than 20 slitting machines available we can offer our customers a diverse range of roll widths (from 3mm up to 1100mm) and lengths to suit their specific production process. From our master reels of coated tape products, die-cut shapes or customised rolls can be produced.

Lamination: PPI offer laminating solutions where several raw materials can be combined to produce multi-layer designs. Materials can be fully, partially or off-set laminated as part of our standard offering. Laminated materials can be offered in continuous roll format or as die cut parts.

Rotary Die-cutting: T.A.P. has 7 rotary die-cutting machines which have the capability to offer bespoke designs to suit your specific needs. With a wide range of materials available including films, foil, fabrics & foam, we offer our customers many formatted possibilities to choose from. Our die-stations are servo-driven which ensure we achieve excellent dimensional accuracy and registration when die-cutting our multilayer laminates or printed products.

UV Flexo Printing: T.A.P. offer the capability to print materials or die-cut parts online using high quality UV cured flexographic inks. These inks have very good chemical, mechanical & environmental resistance.

Consult us

Whether you have a specific design or are just looking for a consultation, our R&D department can offer support and technical know-how on all areas of adhesive tape design and production. Our customers are provided assistance during the entire design and product selection stage and are a valued part of the process.

If you want to get in touch with us, please contact one of our regional sales representative www.ppiadhesiveproducts.com/contacts-ppi-worldwide.