*By clicking Download for free, I agree to the processing of my data for marketing purposes and to receive promotional materials via e-mail. Read our Principles of personal data protection.

Innovative Adhesive Materials for Smart Cards: How Quality Chip Bonding Can Ensure Durability and Reliability

Smart cards, also known as chip cards or integrated circuit cards, are becoming increasingly popular in a variety of industries, including transportation, telecommunications, payments, and identity verification.

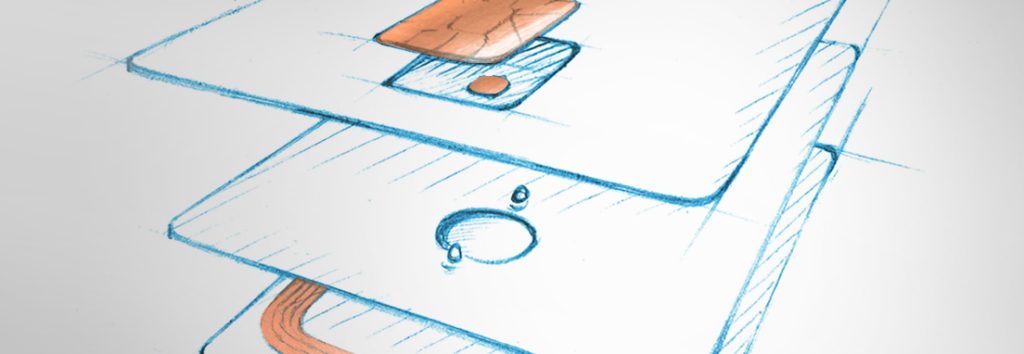

One of the key factors that determine the reliability of smart cards is the quality and permanence of the chip module bonding. The chip module is the core component of a smart card, and it must be securely and permanently attached to the card’s body in order to ensure proper functionality.

The process of attaching the chip module to the card is known as bonding and must be controlled and monitored closely to ensure that the chip module is properly aligned and that the bonding is strong and consistent.

In addition, a smart card’s durability and reliability are also dependent on the quality of the card body and the materials used. Card manufacturers use a variety of materials, including plastic, PVC, and composite materials, to create smart cards that are durable, lightweight, and resistant to bending and breaking.

What to consider when choosing a method of attaching the chip:

- Type of the card – Contact or Dual Interface

- Assembly line possibilities

- Desired chip bonding strength

- The material used for the card, its thickness, and colour of the material

Non-conductive Heat Activate Tapes for Contact Cards

In Contact cards, the chip is bonded to the cavity of the cards. The Heat-sealing film (or Heat-activated Adhesive Bonding film) is suitable for chip module embedding processes for plastic contact cards commonly made from PVC, ABS & PC materials. It provides a long-term reliable solution. Can often be customized based on assembly line requirements.

This type of adhesive tape is utilised in Contact cards, SIM cards, ID cards, Loyalty cards, etc. And is widely used in the Payment, Telecom, Identity, Transport, Healthcare, or E-commerce segment.

Conductive Heat Activated Tapes for Dual Interface Cards

When manufacturing Dual Interface or Non-contacted Cards, the chip is bonded to a card with conductive material. Many manufacturers use conductive paste or conductive glue to bond the flip chip.

Using electrically conductive heat-activated films (or anisotropic conductive films – ACF), for bonding the chip module, can reduce the processes involved in manufacturing and thus increase efficiency.

Electrically Conductive Heat-activated Transfer Adhesive Tapes ensure a secure connection between the antenna and chip module and provide you with higher flexibility.

In Dual interface cards, the mechanical embedding of the chip module and connecting the antenna are performed in a single step. The electrically conductive film is suitable for chip module implanting processes for dual interface cards commonly made from PVC & ABS materials.

Dual interface cards or Contactless cards are widely used in the Payment and Identity sectors.

Conclusion

The market for smart card production is constantly evolving, and this brings many challenges for manufacturers. One of the main challenges is keeping up with the latest technology and trends in the industry, such as the increasing demand for dual interface cards, which have contact and contactless capabilities. Another challenge is to ensure the security and confidentiality of the data stored on the card, as well as the protection against fraud and hacking.

Despite these challenges, the smart card market continues to grow, as more and more industries adopt these cards for their various applications. With the increasing demand for smart cards, manufacturers are working hard to improve their production processes and develop new technologies to meet the needs of the market.

Need help with choosing the right product? Visit the PPI Adhesive Products website and get in touch with one of PPI’s regional sales representatives www.ppiadhesiveproducts.com/contacts-ppi-worldwide.